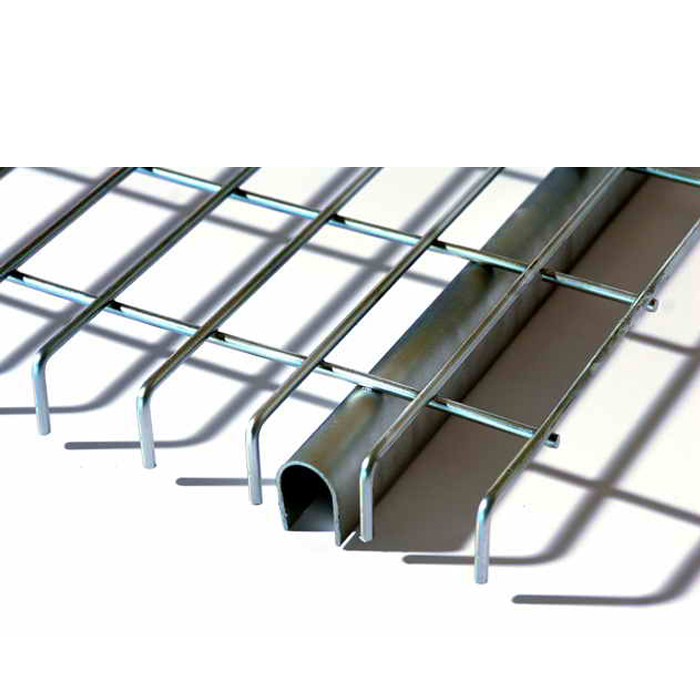

The addition of wire mesh decking to pallet racks expands the racking system’s capabilities. Wire decking between beams is a more robust and long-lasting alternative to wood planks. The mesh design also increases ventilation, which is essential for keeping temperature- and moisture-sensitive items. See how pallet rack wire decking may improve the look of a storage room.

What Is Wire Decking for Pallet Racks?

The open-weave pattern of mesh wire decking is made of sturdy metal. The sections of decking fit between or over the pallet rack’s support beams, depending on the type. Anything that falls off the pallets is caught by wire decks, preventing spills or lost objects from falling to the floor. If items fall from a pallet to a pallet below or the floor without the mesh decking, they may be lost.

Why Go For Wire Decking Over Others?

Wear Resistant

Wire mesh decking is made of robust and long-lasting material. Unlike wood, which can distort and splinter, wire decking from Net-Railing HML does not suffer from these problems. Galvanized decking decreases the possibility of forklifts or pallets damaging the decking. Because pallet rack wire decking does not deteriorate as rapidly as hardwood planks, it is a more long-term investment in sustaining pallets and their loads. Decking is an investment in good warehouse equipment that will last for years, even when used heavily.

No Cutting

Wire decking does not involve cutting and can only fit between beams, whereas wood decking does. To guarantee a great match, each decking fits specified rack sizes. Furthermore, unlike waterfall decking, wood has no means of securing the beams. Wood that isn’t cut properly has a possibility of dropping through the racks or fitting loosely. Why waste time looking for the right fit when wire decking is produced in the correct dimension to provide between step beams or over box beams?

Lower Cost

The expense of cutting, installing, and replacing wood boards overtime for a rack system will be significantly more than the cost of wire decking specifically built for the rack. Wire decking requires minimal to no upkeep once installed. The deck’s durability lowers the cost of the deck throughout the life of the pallet racks it fits into. Buyers discover that the pricing of hardwood boards and wire decking for racks are comparable. Wire decks are significantly less expensive when considering the time it takes to fit wood boards and replace them regularly.

Stronger

Wire decking is more durable than wood. Mesh decking can support a wide range of weights. HML’s wire mesh decking is available in three different euro sizes, with loading capacities ranging from 300 to 1000kg. The weight supported by the decking should never be greater than the capacity of the racks. Such high weights are too much for wood to bear. Furthermore, when wood becomes wet or ages, it weakens, lowering the overall quantity it can hold over time.

Better Lighting

Mesh decking allows light to pass through, whereas solid wood planks prevent it. As a consequence, employees beneath the decks are still able to see well. Wire decking can keep employees safer by preventing trip risks by retaining the area’s illumination.

HML for Pallet Rack Decking Options

If you have pallet racks, replace the wire mesh decking with the appropriate wire mesh decking. If you’d like to get started on selecting the suitable decking, contact us using our online quotation form. We’ll work with you to create a quotation that’s unique to your needs. Allow us to work with you to improve your facility’s capacity to keep what you need securely and efficiently.

CALL +86-15040608276 NOW!