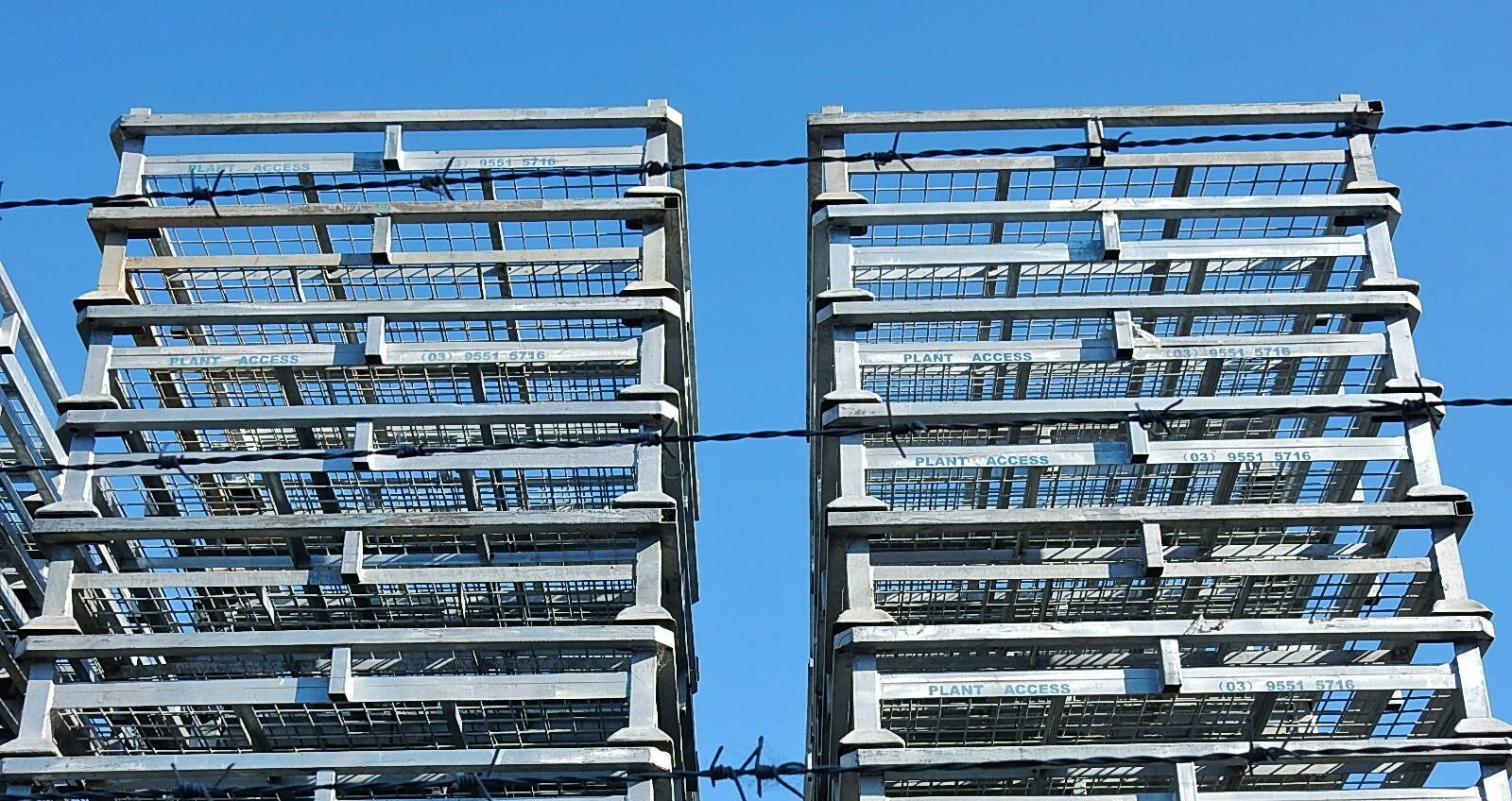

Little do most warehouse managers value metal pallets and its importance during operations. These managers are busy enough to take notice of their conditions. Still, having regular check-ups is a helpful practice to make sure to change metal pallets is in tip-top shape. Damaged and worn out metal pallets not only tamper the productivity of the workers. They also lead to accidents affecting both the warehouse and its workers. Fortunately, this can be avoided by detecting the early signs of pallet deterioration.

Here at Huameilong, our team does not just focus on supplying metal products alone. We also aim in giving the best advice for companies to manage and keep their equipment in good shape for the long run. Hence, here are the warning signs that tell you it’s time to change metal pallets:

The edges are getting sharp

The more a product is used, the more it loses its smooth features. Once you start noticing these sharp edges, you can have these repaired. In worst cases, these metal pallets must be replaced. When left untreated, metal pallets with sharp edges can result in injuries to the employees and accidents during operations.

Product parts are getting detached

When metal pallets are often pushed beyond their capacity, some areas tend to get separated or fall out. Check the structure of your equipment. Are the parts still there? Is the material still intact? If you see a piece missing, you can get a replacement. When more components are missing, you might need to replace the entire product.

The emergence of rust

Rust and corrosion are inevitable when it comes to lengthy product usage. However, these signs are not easily noticed. Employees need to conduct in-depth check-ups on their products to ensure their good condition. Once rust and corrosion are detected, a particular protocol needs to be performed to treat this issue. If the corrosion persists, the best thing to do is to replace the metal pallets.

Product base and other parts are bent

The reason that metal pallets bend is because of either the weight they carry or their durability and capacity to withstand certain mass. Get these products checked once you see them getting bent. If you happen to be using them beyond their loading capacity, change into metal pallets with better durability.

What to do

Employees and warehouse managers should conduct regular check-ups on their products. If the warning signs above are seen, you need to change metal pallets as an ideal precautionary measure. Safety is an important factor in business operations and in achieving true business success.